Winter Vehicle Technology Day: Lixiang’s Approach to Tackling Winter Challenges for EV’s

Last Updated At: 2026-01-30 Author: Sarah

[XNmotor News]

At the beginning of December, Lixiang Auto hosted a Winter Vehicle Technology Day. As the name suggests, the event focused on providing winter driving tips to car owners while highlighting advancements in vehicle manufacturing technologies. The event was centered around addressing the challenges posed by cold winter environments and exploring innovative solutions for new energy vehicles (NEVs), including both pure electric and range-extended models. The event showcased strategies to enhance the driving experience during harsh winters and introduced groundbreaking technologies that set NEVs apart from traditional fuel-powered vehicles.

Image Source: Chinese News Media

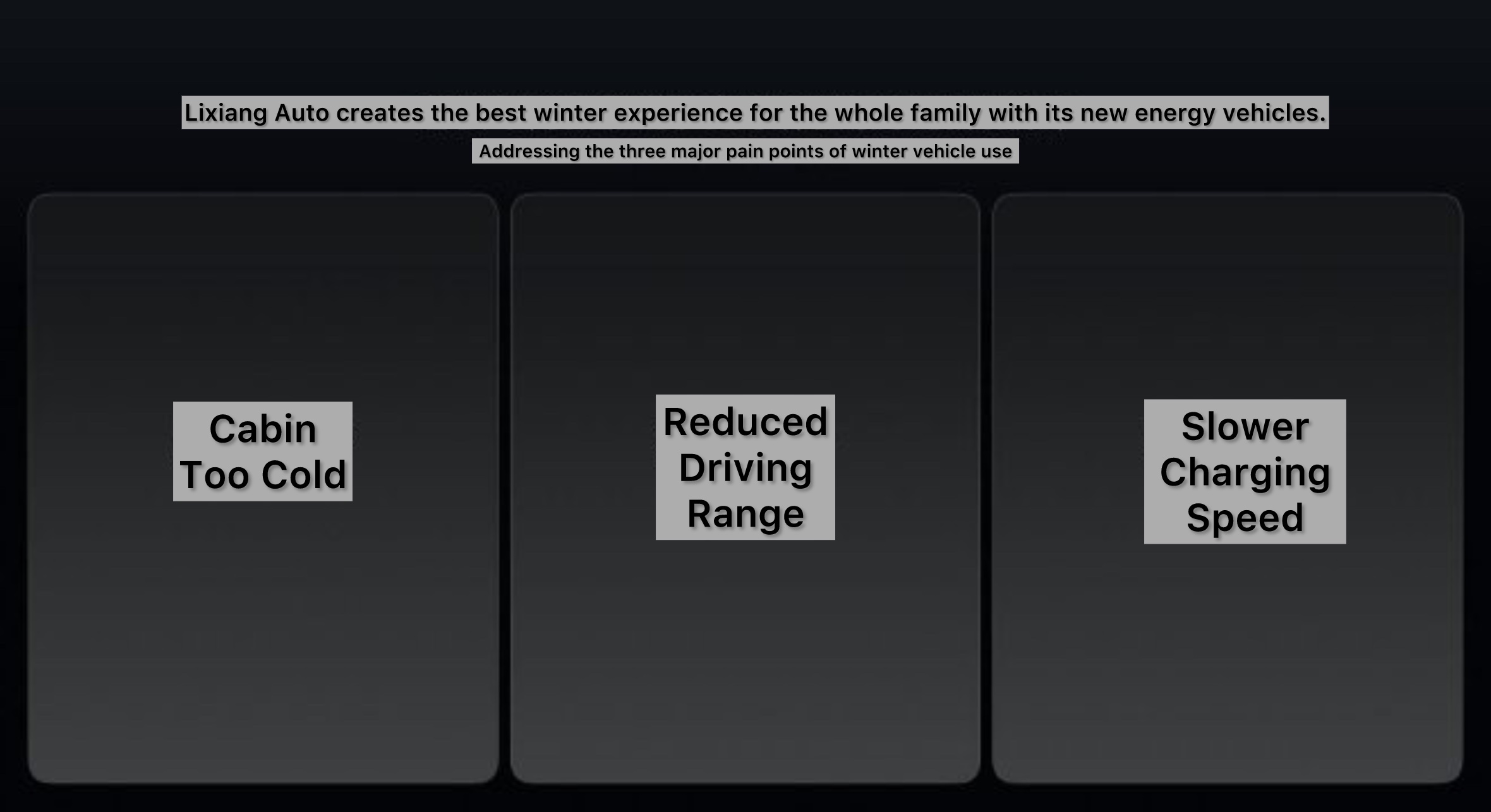

Similar to its previous events, Lixiang Auto’s Technology Day was concise and to the point, diving straight into the core issues. According to Lixiang, the three main challenges faced by new energy vehicles in winter are cold cabin interiors, decreased range, and slower charging speeds.

Image Source: Chinese News Media

Intelligent Cabin Temperature Adjustment: Prioritizing Comfort

A common issue with winter driving is the cabin being too cold. The slow temperature rise and uneven temperature distribution in the cabin have long been product pain points criticized by users of new energy vehicles.

Currently, most electric vehicles in the industry adopt two conventional solutions for winter heating. The most widely used is PTC (a heater for generating heat sources for the battery or cabin), which directly heats water or air for quick and simple heating. However, meeting the heating needs of colder northern regions (-20°C) significantly increases the system’s size, weight, and energy consumption. Additionally, some manufacturers use a hot gas bypass solution, utilizing self-heating through an electric compressor. However, this method has a slow initial heating speed, high compressor speed, and significant noise levels.

To address the shortcomings of these conventional methods, Lixiang MEGA features a self-developed multi-source heat pump system with 43 modes to handle energy allocation across various temperature ranges and scenarios. For poor air conditioning heating performance at low temperatures, the compressor can quickly generate heat independently. By using coolant still warm from air conditioning heating to heat the refrigerant, the heat pump unit is activated, enabling the electric compressor to provide additional heating capacity.

Having stronger heating capabilities does not necessarily guarantee a better comfort experience. Under low-temperature conditions, it is essential to ensure equal heating rights for the first, second, and third rows, avoiding situations where the first row heats quickly while the second row remains cold or heats slowly.

Moreover, in cold conditions, the heat demand for the extremities is higher than for the torso, requiring more heat in the footwell. Providing sufficient heat to the feet under low-temperature conditions ensures better comfort. Additionally, achieving a temperature gradient between the feet and the upper body is necessary to keep the feet warm and the head cool during driving.

From the L9 model onward, Lixiang Auto began utilizing data from 38 vehicle sensors to adjust the cabin temperature in real-time. With the latest generation Lixiang MEGA, additional features such as a carbon dioxide sensor for improved air quality, a negative ion sensor, and signals like weather forecasts and map navigation have been introduced. The number of vehicle sensors now reaches 51, with data processed by Lixiang’s advanced vehicle control computing unit (XCU) to enable intelligent cabin temperature management.

Reducing Energy Consumption: Starting with Thermal Management and Batteries

In winter, reduced range has always been a common issue for new energy vehicle owners, particularly in northern regions. During winter, air conditioning accounts for about 15% of range reduction, while battery loss accounts for about 10%. Lixiang Auto has proposed a “source expansion and cost-saving” solution to address these issues: reducing air conditioning energy consumption while maintaining cabin comfort (cost-saving) and increasing battery discharge performance in low temperatures (source expansion).

For cost-saving, Lixiang Auto has adopted a dual-layer airflow air conditioning box design. This design separates the air conditioning intake structure into upper and lower layers, introducing a moderate amount of external air into the upper space. This mitigates windshield fogging risks while ensuring passengers breathe fresh air. Meanwhile, warm recirculated air is distributed to the lower cabin space, using less energy to keep the footwell warm.

Additionally, using sensors such as humidity, temperature, and carbon dioxide sensors, Lixiang Auto has developed a smarter control algorithm. This algorithm increases the proportion of recirculated air to over 70% without causing fogging, significantly improving energy efficiency. For example, under -7°C CLTC standard conditions, the dual-layer airflow air conditioning box reduces energy consumption by 57W in the Lixiang MEGA, translating to a 3.6km range increase.

Beyond the innovation in the air conditioning box, Lixiang Auto has also made self-developed architectural innovations to its thermal management system, enabling precise utilization of every bit of heat across various winter scenarios and environments.

One common scenario is starting a cold vehicle during morning commutes in winter. Typically, urban driving conditions allow the electric drivetrain to provide residual heat for cabin heating, though the amount of heat is limited. With traditional thermal management architecture, residual heat is passed through the battery for heating before reaching the cabin. However, if the battery already has a high charge level and doesn’t require heating to improve discharge capacity, this becomes an unnecessary energy consumption. To solve this, Lixiang Auto introduced a bypass option in its thermal management system, allowing the electric drivetrain to heat the cabin directly. This approach saves about 12% energy compared to traditional methods.

The thermal management integration module of the Lixiang MEGA combines 16 major functional components such as pumps, valves, and heat exchangers into one, significantly reducing the number of parts. The pipeline length has been shortened by 4.7 meters, and pipeline heat loss has decreased by 8%. This is also the industry’s first integrated module meeting 5C ultra-fast charging requirements.

Improving Winter Charging Speed and Enhancing User Experience

As temperatures drop, battery activity weakens, and charging times for electric vehicles often increase significantly. Under normal conditions, a traditional 2C battery system typically charges from 10% to 80% in about 30 minutes. However, in low-temperature environments, the charging time extends to approximately 50 minutes.

To achieve consistent year-round charging performance with the MEGA’s 5C battery, Lixiang Auto has implemented technical upgrades in both hardware and software. These include high-rate cell designs, efficient thermal management, and multiple intelligent charging control strategies.

The Kirin architecture features a battery thermal management system with an ultra-large heat exchange area. The larger exchange area not only helps dissipate excess heat more quickly in summer but also effectively increases the battery heating speed in winter, enabling the battery to reach the optimal temperature for 5C ultra-fast charging in a short time.

Conclusion

In the rapidly advancing era of new energy vehicles, addressing challenges such as winter conditions requires innovative solutions. Through its Winter Vehicle Technology Day, Lixiang Auto has demonstrated its commitment to improving comfort, efficiency, and performance in low temperatures. These advancements not only enhance user experience but also set benchmarks for the industry.

[ News Article/ XNmotors Sarah ]

Comments

No comments yet. Be the first one to comment.